New technologies in industrial brazing

Traditional industrial brazing is undergoing a transformation, with the introduction of new technology that enhances safety, quality and efficiency, especially significant for industries reliant on high-performance brazing, including the automotive, white goods, storage, racking and shelving, fabrication, and engineering sectors.

Brazing is a crucial process in various manufacturing sectors, allowing for the secure joining or bonding of dissimilar and similar metal components, such as copper to brass, or copper to copper. However, traditional brazing methods can lead to gas leaks, inefficient fluxing, and safety risks owing to high-pressure systems.

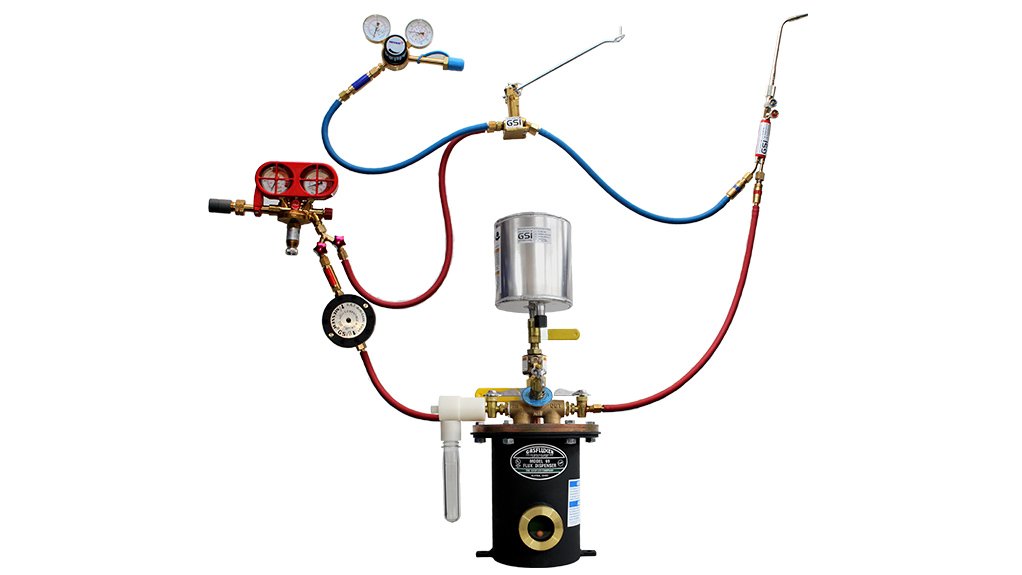

To address these challenges, Gas Safety International (GSI), a subsidiary of South African cutting, welding and grinding consumables and equipment supplier First Cut, has added its S.A.T. regulator, valve and torch to the liquid fluxing system known as the D69. The S.A.T. flux system helps reduce gas contamination risks, enhances gas welding and brazing efficiency and improves operational productivity.

GSI MD Peter Rohlssen highlights the importance of safety in brazing operations: "Our goal is simple: to make brazing safer and more efficient - without compromising performance. Traditional brazing systems are often negatively impacted by pressure-related hazards, contamination, and downtime issues. The S.A.T. flux system tackles these challenges head-on, by ensuring a safer working environment while improving productivity."

The D69 fluxing unit enriches flammable gas (such as acetylene) with liquid flux by passing the gas through a reservoir, where it absorbs the liquid before reaching the torch for brazing. This process enhances brazing efficiency, improves joint quality, and operates under negative pressure to increase safety by preventing backflow, reducing explosion risks.

The S.A.T. flux system also eliminates the need for equipment to be de-pressurised for maintenance or reloading, which allows for uninterrupted workflow.

The system also features a gas economiser with pilot flame, which ensures that the flow of gas and liquid flux to the torch stops when it is not in use, helping to save time and ensure operator safety.

GSI is an authorised service centre for the D69 fluxing unit and the S.A.T. valve is manufactured in its Johannesburg facility. The company also offers training and support for customers adopting the new system.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation